by Anne Katrin Schön

On 12 June of this year, the German Federal Court of Justice (FCJ) in Karlsruhe concluded nullity appeal proceedings (X ZR 96/11) against the German part of European patent EP 1 071 556 B1 by dismissing the nullity action and upholding the patent as granted. Overruling the first-instance judgment 1 Ni 19/09 of the Federal Patent Court (FPC), with which the patent had been declared null and void in its entirety, the FCJ confirmed principles of established case law both regarding novelty and inventive step. Prior to the German nullity proceedings, the European Patent Office (EPO) had rejected an opposition against the patent. A comparison between the EPO, FPC and FCJ decisions shows that the definition of the problem underlying the claimed invention had a major influence on the respective, and deviating, conclusions regarding inventive step.

1. The wide ply patent

European patent EP 1 071 556 is directed to tubular paperboard cores for winding paper webs which are used e.g. in printing presses. When manufacturing such cores, strip-shaped plies (layers) of paperboard are glued one on top of the other and wound spirally in a special spiral machine.

The patent aims at improving a particular strength parameter of such paperboard cores, referred to as the “chuck strength”. “Chuck strength” is the ability of a paperboard core, and more particularly of the end sections of the core which are clamped by short chucks (radial clamps), to withstand the load caused by the weight of the paper roll during winding and unwinding of the paper, i.e. during the rotation of the core.

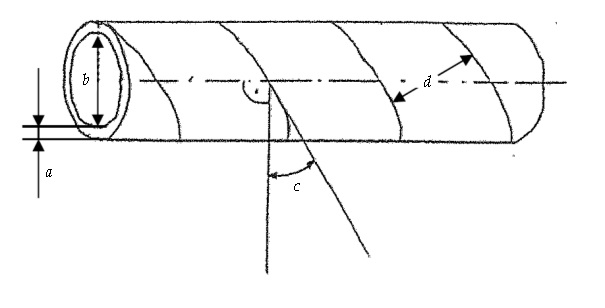

Claim 1 of the patent protects a method of manufacturing a spiral paperboard core, and claim 7 protects a spiral paperboard core as such. In both claims, the paperboard cores are said to have a certain minimum wall thickness a, and an inner diameter b within specific ranges. Furthermore, the paperboard plies, from which the paperboard core is made, are said to be wound under a certain winding angle c which is specified for each of the different ranges of inner diameters b. The winding angle in turn results in a specific width d of the individual plies, which is wider than in the prior art. This is why the patent has also become known as the “wide ply patent” and will be referred to accordingly in the following.

It can therefore be said that the claimed paperboard cores include features a (wall thickness) and bc (combination of inner diameter b and winding angle c), or a (wall thickness) and bd (combination of inner diameter b and ply width d). The respective dimensions a to d are illustrated in the schematic drawing below.

The application for the wide ply patent was filed in 1999. The patent was granted in 2002 and under EPO opposition until 2009. The Opposition Division rejected the oppositions. One of the Opponents, a main competitor of the patent proprietor, filed an appeal but then withdrew it to be able to initiate national German nullity proceedings. According to Sec. 81 (2) German Patent Act, a nullity action may not be brought as long as opposition proceedings are pending. The appellant obviously hoped for a better outcome in German nullity proceedings than in the opposition appeal proceedings before the EPO. Whether this is due to arguably different approaches to inventive step or due to the fact that he wanted to introduce a new prior art document remains a matter of conjecture.

In parallel to the nullity proceedings, the patent proprietor initiated infringement proceedings against the Plaintiff.

2. The Prior Art

Throughout the EPO opposition proceedings and the two instances of German nullity proceedings, the same prior art was basically asserted. The two key citations, which will be designated C1 and C2 here, were already known from the International Search Report:

C1 – the utility model also owned by the Respondent/Defendant – was directed to a measure to improve the axial stiffness of paperboard cores by using a raw material having a specific E-modulus. C1 made it clear that the core construction need not be changed in any other manner except for the raw material. In this context, C1 disclosed paperboard cores having a wall thickness a and inside core diameters b as claimed (this was undisputed between the parties). Commonly used winding angles c and ply widths d were mentioned in C1, and certain combinations of the disclosed inner diameters b with the mentioned winding angles c or ply widths d would have resulted in geometries within the claimed ranges. However, C1 failed to explain which winding angles c, or ply widths d, were to be used with which of the stated inner diameters b, so that actually no combinations bc or bd were explicitly disclosed. The drawings of C1 further included a graph in which the E-modulus was plotted over the winding angle.

C2, published in the 1960s, disclosed paperboard cores having inner diameters b and winding angles c which resulted in combinations bc inside the claimed range. The wall thickness a of these cores was, however, far below the claimed minimum value. This was due to the fact that the paperboard core of C2 was designed to improve the beam strength and radial crush strength of the core, i.e. still different properties than those discussed in C1 (axial stiffness) and in the wide ply patent (chuck strength).

3. The decisions

All three instances decided on the validity of the wide ply patent in light of these two citations C1 and C2.

The EPO Opposition Division confirmed that no combination of a particular ply width d with a particular inner diameter b was suggested in C1, which meant that the claims were novel. Regarding inventive step, the EPO emphasized the importance of properly formulating the objective problem underlying the claimed invention, which it found to be that of improving the chuck strength of the paper core (rather than improving the core strength in general as alleged by the Opponent – the EPO recognized that improving one strength parameter can lead to a reduction of another, and therefore a “general strength” of the core cannot be defined). In light of the so (i.e. narrowly) defined problem, the prior art – including C2 – was found to provide no hint to the claimed solution.

The Federal Patent Court, in contrast, found the claims to be not novel or at least not inventive over the disclosure of the same citations C1 and C2. For novelty, the FPC stated that the skilled person would take from C1 a paperboard core having not only the claimed wall thickness a, but also an inner diameter b in combination with a winding angle c within one of the ranges specified in the claims. It was conceded in the judgment that the indications regarding the winding angle are not directly attributed to the diameter indications in C1. However, the fact that the angles c are given irrespective of the inside diameters b in C1, and the assumption that combining each of the inside diameters b disclosed in C1 with each of the winding angles c in the range disclosed as common in C1 did not provide “entirely unreasonable” results already sufficed for the FPC to conclude that the claimed paperboard core was in fact anticipated by C1. The FPC further stated that even if the claims were novel, they would not be inventive, arguing as follows: “In the drawing of C1, the connection between a larger winding angle and an increasing E-modulus is shown, which is a parameter of strength. (…) Therefore, the skilled person had a reason to consider a larger winding angle when he wanted to take into account the increasing demands vis-à-vis the strength of the paperboard cores.”

It was apparent that the FPC relied on a very broad definition of the problem underlying the claimed invention as being that of providing paperboard cores with “improved mechanical properties”. With this definition of the problem, the FPC did not even consistently differentiate between strength and stiffness properties of the core, and went beyond the improvement of a “general strength” which the EPO had found to not exist. Of note, the FPC explicitly addressed the foregoing EPO decision in its judgment and stated that an “object directed exclusively at an improved chuck strength”, as defined by the EPO, was “not solved by the paperboard core of the claims”. The FPC did not further explain why it deemed this object not to be solved, and addressed neither the fact that the wide ply patent does illustrate how the chuck strength improves with the claimed inner diameter-winding angle combinations, nor the fact that the improvement in chuck strength provided by the claimed core geometries was not even ever denied by the Opponent and Plaintiff. Provided that this is certainly one of the key points in the decision of the FPC, one would have wished for a more detailed discussion of this issue.

In light of the decision of the FPC, the infringement proceedings were stayed pending the outcome of the nullity appeal proceedings.

The Federal Court of Justice overruled the judgment of the FPC and decided that the claims are novel and inventive. As to novelty, the FCJ criticized the standard applied by the Federal Patent Court, in particular regarding the FPC’s allegation that an association between the inner diameter b and the winding angle c could already be derived from C1 because the resultant teaching would not be regarded as “entirely unreasonable” by the skilled person. The FCJ confirmed that this is not sufficient for a clear and unambiguous disclosure, explaining that, if the citation C1 does not indicate an association between the diameter and the angle. Such an association might at best be inferred by the person skilled in the art owing to his expertise. According to the FCJ, such an inference was out of the question here.

Regarding inventive step, the FCJ found that – again in contrast to what was stipulated in the first instance judgment – C1 did not provide the person skilled in the art with an incentive to configure a method and paperboard core according to the wide ply patent. The FCJ based this opinion inter alia on that the object defined, i.e. a higher chuck strength, was not addressed in C1 as a target to be achieved, and that C1 further stated that the core construction need not be changed in any other manner except for the raw material. The FCJ found that “in view of these clear indications, there is no reason – in contrast to the opinion of the Patent Court – to change the winding angle, in particular to (significantly) increase it within the terms of the invention. On the contrary, the person skilled in the art is encouraged to change the structural layer material only”.

The FCJ also ruled in favour of an inventive step of the wide ply patent in view of the second citation C2, arguing as follows: Even though the claimed inner diameter-winding angle combinations are disclosed in this citation, the cores which have these geometries are thin-walled and supposed to provide the core with radial crush strength and beam strength. No mention is made in C2 of a required chuck strength, let alone a necessary increase thereof. Consequently, the person skilled in the art would not have gathered motivation from C2 to provide the winding angles disclosed therein for a core, the chuck strength of which is supposed to be improved. On the other hand, no reason can be derived from C2 for the person skilled in the art to significantly increase the wall thickness of the cores disclosed therein so as to arrive at what is claimed.

4. Conclusion

Regarding inventive step, the FCJ confirmed that as a rule an incentive is required for the skilled person to arrive at the claimed solution in view of the problem posed.

An apparent similarity between the decisions of the EPO and the FCJ resides in the definition of the problem underlying the claimed invention: Both the EPO and the FCJ confirmed that the problem underlying the invention is actually (only) that of improving the chuck strength – not because this problem is already defined in the patent in suit, but first and foremost because this is the actual contribution which the invention makes to the prior art. For a reason that does not become perfectly clear from the nullity judgment, the FPC defined the problem much more generally, and in the end this made a significant difference regarding the evaluation of inventive step.

Furthermore, the FCJ confirmed the standards for a clear and unambiguous disclosure. In particular, in order for a combination of parameters to be clearly and unambiguously disclosed in a prior art citation, it does not suffice that the skilled person considers this combination to be not entirely unreasonable.

Finally, the present case has also shown that even without any exceptional delays, the prosecution, opposition and German nullity proceedings can easily consume the biggest part – three quarters in the present case – of the maximum lifespan of a patent.

________________________

To make sure you do not miss out on regular updates from the Kluwer Patent Blog, please subscribe here.