A few days ago, our Kluwer News Blogger reported on a decision in the Netherlands, holding two Dutch patents for processing the Ethiopian grain “teff” as null and void. While this decision certainly has a political dimension, which formed the focus of the reports in the general press and the report from the Norwegian Fridtjof Nansen Institute, it also has a dimension extending into the issue of patent quality. Let me explain why:

One of the two patents was EP-B-1 646 287, titled “Processing of Teff Flour”. Its Claim 1 reads as follows:

1. A flour of a grain belonging to the genus Eragrostis, preferably Eragrostis tef, characterized in that the falling number of the grain at the moment of grinding is at least 250, preferably at least 300, more preferably at least 340, most preferably at least 380.

So the claim seems to pertain to the Ethiopian grain Eragrostis tef (also known under its common name Teff), characterized by a certain parameter, i.e. the “falling number of the grain at the moment of grinding”.

I have to say that claims of this type always make me quite curious, not to say suspicious. Two questions immediately spring to mind: (i) What is so special about this parameter, and (ii) how does one obtain a teff satisfying this parameter?

The patent firstly explains at length that teff is a great grain. It is gluten-free and thus very suitable for babies or persons suffering from a gluten intolerance such as celiac disease patients. Besides, it seems to be a great crop for our changing climate, as it does not make high demands on the nutrient medium and the climate and is particularly well resistant to drought. So far, so good. Then the patent continues in [0010]:

[0010] In summary, Eragrostis offers an attractive source of (gluten-free) flour. However, it has been found that the preparation of a food product with traditional Teff flour (for instance Teff flour which is mixed with wheat flour for preparing injera) often causes problems. A known problem is the instability of the product, particularly of baked products. In other cases, the product has an unattractive taste and/or structure.

[0011] The invention provides the insight that the above-mentioned problems surprisingly do not occur if Teff flour with a particular falling number is used.

Okay, so now we know which advantages are said to be associated with the magic parameter of the “falling number”. And it gets even more interesting:

Different Teff varieties have been tested in different after-ripening stages and under different cultivation conditions (such as climate, soil type, fertilization) on test and cultivation fie lds. Samples hereof have been collected and analyzed for inter alia falling number and baking quality (with test breads prepared according to the formulation and method of Example 1).

This shows that a falling number of at least 250 is needed to obtain a baking product with an acceptable quality, that is, a product that is awarded at least a grade 5 (on a scale of 1-10) by a test panel. A falling number of 300 results in a significantly improved product (assessment: 6), while a product of Teff flour with a falling number of 380-390 is, on average, awarded the grade 7. It can be gathered from Fig. 1 that, for a product which meets the ’market standard’ of 7.5, the use of Teff flour with a falling number of at least 400 is required.

Wait a minute? A baking product “with acceptable quality” is supposed to have a falling number of at least 250? But isn’t this what the claim is supposed to cover? So does the claim cover all baking products made of Teff having an acceptable quality? It indeed seems so.

Now, the patent further discloses (in [0007]) that Teff has been cultivated for human consumption in mainly Ethiopia and Eritrea for more than 5000 years, and that it is traditionally used for preparing injera, a spongelike, gray pancake. This leaves only two possibilities: Either these people from Ethiopia and Eritrea never managed to produce a baking product (such as a pancake) with acceptable quality for the last 5000 years. Or there is perhaps something wrong with this patent claim.

Which brings me to question 2, how is teff obtained that has a falling number of at least 250? The patent does not hide the answer, one just has to read further:

[0014] The traditional Teff flour, which is obtained by grinding the grain directly after the harvest, still causes problems with the processing thereof in baked products, as elaborated upon in the introduction. The invention now demonstrates that the reason for this is that, directly after harvesting, Teff grain of known Teff varieties has too low a falling number (that is, lower than 250) to be processed into an attractive product.

[0015] It is generally known that grain goes through an after-ripening process after harvesting, in which the falling number of the grain increases. Preferably, a flour according to the invention is obtained by storing the harvested grain kernel and/or having it after-ripen for some time and only grinding the grain after the falling number has reached a value of at least 250.

So the trick is not to use the teff directly after harvesting, but to store it for a while before grinding. And it seems that it was even “generally known” that by such storing (and “after ripening”) the falling number increases. Hmm.

Next, I wondered how long does teff have to be stored to have a falling number of more than 250 and thus fall under claim 1 of the patent at the time of grinding? The patent in [0015] does not conceal the response:

The invention provides flour of Eragrostis spp. grain, with the grain having been ground at least 4, preferably at least 5, and more preferably at least 8 weeks after harvesting. Such a period is usually sufficient to obtain grain which has after-ripened sufficiently and has a falling number which meets the above-mentioned conditions.

Thus, the conclusion appears pretty compelling that this patent protected any kind of teff, when stored at least 4 and preferably at least 8 weeks after harvesting, before being ground.

And people never thought about storing teff for a few weeks or longer before using it?

I have not carried out a prior art search but I find this extremely hard to believe. Musing about what people may have done with grain even a couple of thousand years ago, my old bible came back to my mind. And it turned out that Genesis 41, 33 is at least a nice Y document, in my humble view. Here is what Joseph advised the Pharaoh:

33 “And now let Pharaoh look for a discerning and wise man and put him in charge of the land of Egypt. 34 Let Pharaoh appoint commissioners over the land to take a fifth of the harvest of Egypt during the seven years of abundance. 35 They should collect all the food of these good years that are coming and store up the grain under the authority of Pharaoh, to be kept in the cities for food. 36 This food should be held in reserve for the country, to be used during the seven years of famine that will come upon Egypt, so that the country may not be ruined by the famine.”

Which brings me to my real question: How could such a patent claim ever be granted?

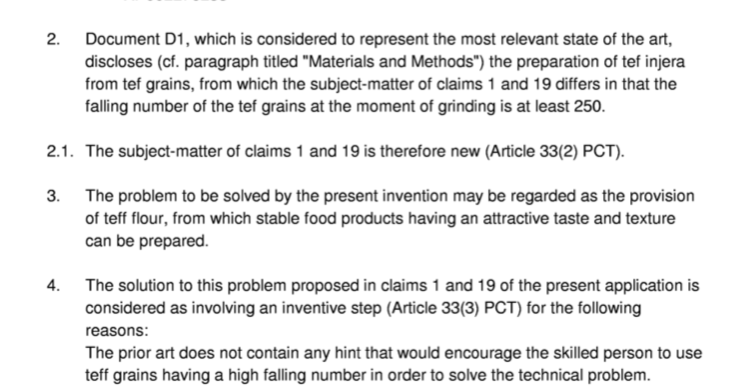

The examiner seemed to have had no difficulty with it. It was a direct grant following a positive IPER, where the following was stated:

All quite understandable, at least if one limits the examination to a reading of the claim and the paragraph stating which problem the claimed invention is to solve.

Yet, somehow this grant leaves a certain feeling of discomfort.

_____________________________

To make sure you do not miss out on regular updates from the Kluwer Patent Blog, please subscribe here.

Kluwer IP Law

The 2022 Future Ready Lawyer survey showed that 79% of lawyers think that the importance of legal technology will increase for next year. With Kluwer IP Law you can navigate the increasingly global practice of IP law with specialized, local and cross-border information and tools from every preferred location. Are you, as an IP professional, ready for the future?

Learn how Kluwer IP Law can support you.

Just a normal day at the patent office….

I also have concerns about the clarity of claim 1. Any element qualified by the word “preferably” is not limiting. The applicant has effectively added four dependent claims into claim 1 and avoided paying claim fees for them. If nearly half the words in the claim are irrelevant to its interpretation, how can that be clear and concise?

Hi Peter – thanks for asking this question, I’m sure you’ll get many different interpretations but here’s my take:

According to Article 84 EPC: The claims shall define the matter for which protection is sought. They shall be clear and concise and be supported by the description.

The clarity of a claim relates to how clear this definition is – i.e. would a skilled person after reading the claim know where the line between infringing the claim and not infringing the claim lies.

Leaving aside the points raised by Thorsten (i.e. assume that the rest of the claim is clear and not just claiming a result to be achieved (which may not even be novel)) – my view is that (as you note), any element qualified by the word “preferably” is not limiting – as such, the scope of the claim is clear – the definition of the matter for which protection is sought is clearly not limited by the terms falling after the word “preferably” and the the terms falling after the word “preferably” do not cast doubt on what comes before.

As you also note, the Applicant has effectively added four dependent claims into claim 1. As such, the claims are actually more concise. Note the use of the plural in Article 84 EPC.

It’s an interesting question as it raises a philosophical point – clarity is very important on our side of the fence, but it’s more a question for us of how well will the claim work after grant – i.e. the last thing an applicant wants is a situation where the boundary of what falls within the claim is to unclear. This potentially will not protect their innovation because no one knows where the scope of protection starts or ends.

For us, a claim with the sort of ‘preferably’ language used in the claim above functions no differently to the use four dependent claims – the scope is identical and everyone understands what is covered and what is not.

My understanding is that at present on the Examiner’s side of the fence clarity is being used as a metric internally to measure the quality of patents granted by the EPO. However, this review appears to be decoupled from the underlying question of how the claim will work post grant. This is not surprising as an Examiner is not exposed to these sort of post grant considerations during their normal work. As a result, clarity is turning into an increasingly rigid examination of whether a claim has the correct ‘form’ rather than a review of whether or not the limits of protection are clearly defined. Viewed in this light, the use of “preferably” in a claim looks non-standard, and I’ve certainly had Examiners objecting to “preferably” or even the use of the word “or” in a claim.

I believe that as Examiners and Applicants are coming at this issue from completely different frames of reference it’s regrettably resulting in more work for both sides.

Also, interestingly, the national courts of EPC states are not interpreting claims as rigidly as the EPO. So at present EPO practice on clarity appears to be out of line with the practice in EPC states on clarity.

I hope this make sense!

The objection to “or” in a claim is usually because the claim language covers up a lack of unity, lacks novelty in at least one alternative or leads to lack of clarity in dependencies. Applicants who attempt to combine multiple PCT claims into 15 EPC claims often use this structure without thinking through the new possible combinations.

The point re: combining multiple PCT claims into 15 EPC claims is a good one – if you’re not careful, you’ll do something daft that leads to lack of clarity in dependencies, or the dependencies being incorrect. But I’ve never heard of using ‘or’ in a claim to cover up a lack of unity – it frankly wouldn’t work.

A negative of using ‘or’ in a claim from our side is that it does the opposite of covering up a novelty problem – if a first alternative lack novelty, an Examiner will spot it and raise an objection against it. The Examiner will stop at this point as it’s up to the Attorney to fix the novelty problem. The result of this is that a second alternative that is novel does not get reviewed by the Examiner, so the novelty of this second alternative gets hidden from the Examiner. The same goes for lack of clarity within one of the alternatives.

On the other hand, using multiple dependencies and ‘or’ language, if used correctly, one can usually reduce a claim set of 30 claims to 15 claims without it causing difficulty for the Examiner or the Attorney – this saves the applicant over 3,500 euros. At those costs, we’d be mad not to.

Mr Gillespie,

By ‘hidden’, I was referring to the claims which combine different parameters e.g. process time of about x and/or process temperature of about y, where the two parameters may or may not be combinatory but are claimed individually and produce their own distinct effect.

Thank you Thorsten, for another alert.

No comment yet, on patentable novelty (or not) or inventive activity (or not). Let me remedy that.

By now, patent drafters are drafting with the EPO’s “problem and solution approach” in mind. EPO Examiners should have this in mind too, and examine sceptically the seductive stories they are subjected to, of plausible cause and effect, seemingly valuable correlations, and of apparently useful and non-obvious solutions to supposed technical problems. That said, it would not have been hard, with this particular case, for a diligent Examiner, given a reasonable amount of time, to have put together a persuasive case why this particular claim lacked novelty. These days though, is an EPO Examiner given enough time and incentive to examine diligently?

In a great many other cases, of course, it is all but impossible, ex parte, to rubbish the Applicant’s plausible sales pitch. How do you challenge the comparative data, for example. What it takes, in such cases, is somebody i.e. an Opponent, explaining, with evidence, how Applicant’s story is a load of horse hockey (or bovine excrement). An inventor deserves his or her “day incourt” sure, but then again, the public is entitled to expect the EPO not to be asleep at the switch.

What next, for goodness’ sake? Perhaps this:

What I claim is: Bottle of wine having a BS number of > 250.

Specification: Our insight is the surprising one, that high BS numbers deliver wine with a nicer taste. What do you do, if you want to increase the BS number? Store your bottle of wine in a cellar for a year or two, before you open it and drink it.

EPO Examiner: Novel. No mention in the stae of the art of any such thing as a BS number. Therefore it did not form part of the state of the art. Inventive. The state of the art contains no hint or suggestion to select for drinking wines with a high BS number.

Come on EPO. You can do better than that.

As Mr Bausch would say, let me add my 5p of comments.

The definition of the Falling Number is to be found for instance in Wikipedia:

https://en.wikipedia.org/wiki/Falling_Number

To sum it up, it is a viscosity measure, and is the internationally standardized (ICC 107/1, ISO 3093-2004, AACC 56-81B) and most popular method for determining sprout damage.

The higher the falling number, the less sprouting or germination has occurred.

The claim might indeed be novel, but I have strong doubts about inventive step. It seems pretty obvious that the longer the grain is stored in a dry place, the better it will be usable for baking. This is also in a nutshell the conclusion of the Dutch court.

By merely looking at the definition, it might not be a surprise that this feature applies not only for Teff, but for any other cereal used for baking.

For the different types of flour to be used in backing the following link gives a good insight:

https://whatscookingamerica.net/Bread/FlourTypes.htm

An interesting insight is also to be found in the following link:

https://www.buhlergroup.com/global/en/services__technology-centers-test-facilities__bakery-innovation-center__latest-news__details-11173.htm

Disregarding the dates of the present documents(which should not be done, but for the sake of simplicity is done) one comes to the conclusion that the mere fact of storing grain before milling is well known for improving the quality of the backed product.

The examiner might not have found the right documents, but it does not hinder anyone to look a bit deeper in the matter. It was a quick and easy grant, without too much effort, so what… And whether he should in this case have used the PSA appears to me secondary.

In this respect it is quite surprising that, at the time, the opponent against EP 1 646 287 B1 only raised an objection of insufficiency, but not of lack of novelty or inventive step. The appeal against the rejection of the opposition has eventually been withdrawn.

The claim as such is clear, as it simply defines the minimum quality the flour should have, i.e. FN>250, but better, i.e. preferably FN>300 etc. There is also no problem with unity as the different values are like Russian dolls, and quite common in for instance chemistry/pharmacy. There is as well no problem of rigidity on the side of the examiner, at least in this case. He should simply have thought twice before granting such a patent. Has he never heard about traditional knowledge? It might be more difficult to find, but certainly not impossible.

An interesting insight is also given in IPKat

http://ipkitten.blogspot.com/2019/02/dutch-court-rules-that-patents-based-on.htm

From IPKat it seems that another issue was at stake that is an access sharing agreement between Ethiopian authorities and the directors of the patent owning company. However, by holding the patents, the export of Teff flour by Ethiopia was blocked….. A very interesting read.

The whole story reminds me of the dispute around the products of the Neem tree a few years ago. Here again, a patent was granted for a natural resources, but, if I am right, the opposition by an association of Neem tree breeders was successful. Ethiopian farmers might not have had the same amount of money.

This comment is not to be reused by Techrights in any form whatsoever

“The examiner might not have found the right documents, but it does not hinder anyone to look a bit deeper in the matter. It was a quick and easy grant, without too much effort, so what… And whether he should in this case have used the PSA appears to me secondary.”

Well, as it is an EPO grant, it was not only the examiner… So 3 guys/gals couldn’t be bothered to actually read what they grant?

When I am reviewing grants, I get very suspicious if the claim is so short and has so few features.

R Gillespie writes on Art 84 and “clarity”, in a way that invites a response.

No claim granted by the EPO was ever “clear” to a level of 100%. With mere words, you can only ever approach perfect clarity assymptotically (at least in engineering cases). What matters is whether the claim is clear enough, fit for purpose.

Richard asserts that no Applicant ever desires an unclear claim. I doubt that. I had thought that, at least in the USA, the highest expression of the drafter’s “art” was a claim that reads narrowly when its validity is under attack post-issue, but widely when it is being asserted against a competitor. Litigators demand of those who draft a claim that can be bent like a nose of wax, to mean what they want it to mean (more or less) in the given circumstances, before whatever forum.

I had always thought that the EPO crusade on clarity was because Art 84 is not a post-issue ground of revocation, so the EPO’s highest duty is to ensure that the only claims that get to issue are ones that are clear. With “preferably” I do not see how that in itself offends Art 84 EPC, particularly in these times of infringement by equivalent.

Given that Art 84 is not a ground of revocation, I should like to hear more from Richard on his “out of line with the EPO” comment.

Hi MaxDrei – I believe you’ve misconstrued my comments: no one wants a claim that is too unclear to enforce – i.e. will the claim work as intended? An unclear claim may encompass more subject matter than intended, rendering the claim invalid through e.g. lack of novelty.

I agree with you that no claim granted by the EPO was ever “clear” to a level of 100%. My understanding is that the EPO is hot on clarity at the moment is because it is a metric that is being used to measure patent quality. I do not believe there was ever a significant issue with clarity post grant prior to this crusade. My worry is that the EPO as an organisation is aiming for claims having 100% clarity and perfect ‘form’.

I’m happy to be corrected on this, especially if you have examples from your jurisdiction, but I believe national courts are not reading claims in the same way as the EPO and, for example, clarity is not directly an issue during post grant proceedings before national court. The problem at that stage is that a lack of clarity results in novelty / inventive step issues. I am unaware of a case in a national court where a patent has been revoked for being unclear.

What to say? Post grant, courts have to make the best of what they are given by the EPO. It is not within their powers to hold a claim unclear or ambiguous. Prior to grant, ED’s will try their hardest to find in any given claim any sniff of unclarity, any offence against the provisions of Art 84 EPC. Is that “not reading claims in the same way? Maybe, but is it not a good thing, that duly issued claims are immune from attack under Art 84? If they were, there would be no end to Art 84 attacks on validity. And all for what?

As to your “nobody wants an unclear claim” I still beg to differ with you. Must I remind you of the Franzosi Angora cat claim metaphor. In the infringement court, with all its long hair on end, it appears magnificently large and intimidating. In defence, in the nullity court, soaked to the skin, its tiny body is vividly apparent. Corect me if I’m wrong, but for every single claim asserted in the UK there are perhaps 50 asserted in that well-known bifurcated jurisdiction, Germany.

As to your “metric” point, I agree. Quality managers need something they can measure. They think they can rapidly assess performance of individual Examiners under Art 84 and 123(2) EPC. They know they cannnot quickly assess performance under Art 52, 54, 56 and 83. So they devote al their efforts to imposing compliance on Art 84 and 123(2). Sad!

Hi Max – I think I see where you’re coming from, but I’m not sure you follow where I’m coming from.

I did not say “nobody wants an unclear claim”, I said “nobody wants a claim that is too unclear to enforce.”

To use your cat analogy, a cat that can put it’s hair on end and pull it back in again is still clearly a cat. I don’t see a claim functioning as you suggest as having a clarity problem – as you pointed out earlier, a claim that functions in this way is the height of our art. But an unclear claim may encompass more subject matter than intended (emphasis on the word intended), rendering the claim invalid through e.g. lack of novelty. If your ‘cat’ is actually a dead parrot then I suggest you may have a problem.

Reading back I could indeed have been clearer on my point re: post grant clarity, so I’m to blame for any misunderstanding on that point (apologies). To put the point differently: I’m sure you’ve been around long enough to remember the time before the current clamp down on clarity issues. Do you remember the courts in your jurisdiction having any difficulty working with what they were given by the EPO back then because of clarity? The norm was for EDs to do excellent work. So I’m not sure that the present drive for clarity has any post grant benefit for courts.

My experience with the current dive for clarity by the EPO is that it has been mostly unconcerned with the question of whether the scope of protection defined by a claim is clear and more a question of the claim having the correct ‘form’. As such, I believe the Examiner are being forced to judge claims based on their form (as it’s also quicker), whereas a court will judge claims based on substance. Therefore, I believe they are reading claims differently and the divergence is increasing.

I’m going to leave it at that as I fear I won’t have time to respond to any further points you may raise, but I do hope this at least partially bridges the differences between our positions.

All the very best!

Dear Thorsten and others,

This is an interesting application. However, I don’t think the treatment of this application demonstrates a low quality, as some of you imply.

It has been opposed in 2010 and the opposition was rejected. If this grant was really of such poor quality, an opposition would have easily succeeded, don’t you think so?

The court in the Hague has only revoked the patent based on a newsletter that was sent to participants of the Teff growing project of the proprietor, by the proprietor himself, before his application was filed. After hearing witnesses, the court has decided this newsletter was public information and state of the art.

Infringement procedure started in 2014! Surely, if this patent was obviously invalid, the court would have been able to revoke it years ago!

I’m interested to hear the opinion of someone with knowledge of Teff and this patent.

The fact that an opposition against this patent was filed, which was exclusively based on insufficiency, and rejected by the OD does in my view not necessarily support the quality of the patent – but it also does not speak against it. I think it is simply neutral in this respect.

If anything, it rather raises questions with regard to the quality of this particular opposition. Us representatives are well advised not to assume that the quality of our products is always beyond reproach- it isn’t.

I hope that we, as a society, also take into account the costs that poor patents have for the businesses that strive to be compliant. In particular in a bifurcated system, where infringement and validity are separate matters and you cannot defend yourself with the argument, that the patent is not valid, many resources are wasted to safeguard against poor patents. Clarity and unclear scope are often an issue as is poor analysis of patent-ability. Costs for non-infringement opinions, gathering of evidence for prior use right etc. are immense. Often, products are not developed due to the legal risk, even if the patent has questionable validity but is in force in five or six countries. I feel that this affects the classical, non-litigious industries where where managers want to be compliant and check all the boxes most while the tech-savy firms or troll firms simply ignore bad patents. I think that this is however not good in the long term as it undermines the respect for the law in our society.

Having worked as an attorney and now working as an inhouse counsel, I feel that we all pay dearly for the EPO’s drive towards efficiency.

Dear Anonymous,

That you defend the EPO is your good right. But In think there are better causes to defend that this one.

Opposition is not a quality marker for the grant procedure as not more than 5% of patents are opposed yearly. This is not an opinion, but a fact.

The only way an opposition could give an indication about the quality of the grant procedure is when the patent is revoked in view of prior art which should or could have been found during grant.

In case of an opposition, I would also not necessarily blame the representative. If the client is not giving better documents/arguments than those which were presented in the present case, the best attorney cannot obtain a good result. One can see this times and times.

The opponent was the Chamber of Agriculture from Hannover. That it opposed the patent was not a surprise, as it could feel the commercial problems which could come up, but that it did not come with anything better in respect of prior art is somehow surprising.

We can leave aside the problem of traditional knowledge, but when reading the application, some light should have gone on in this respect.

It is clear that traditional knowledge was not the source of the lack of inventive step. It was a pre-publication by the applicants which was fatal. The problem with traditional knowledge is that is often not written down with all the certainty needed in the patent business.

On the other hand, merely browsing through general literature about flour and baking, one gets the feeling that the flour claimed was the mere result of trial and error. It appears to be a well-known fact that flour has better baking qualities when the grain is stored before milling. This is valid for lots of flours from different grains, and it can hardly be surprising that it applied to teff grains.

But there is sometimes some justice. Wanting to sell stuff before having filed an application on it, is nothing new. It happens times and times.

A court can only decide with evidence put to it. It cannot produce evidence. And it was apparently more efficient to use the own publication of the applicants. But I am convinced that other lines of argumentation would have been possible. See above.

I can only encourage readers to have a look at IPKat. It explains very well what happened. There is also an interesting comment to read.

The claim is extremely broad, and this alone raises suspicion as has been said by some commenter.

One cannot blame the examiner for not finding the pre-publication of the proprietors, but letting such a broad patent slip through is a different matter.

The so-called X documents were probably no X documents as the same examiner cited a different document in the IPER. At a glance this document was closer than those on the ISR. The reasoning in the communication is however a bit summary to say the least: I found something better for teff, and the parameter is not suggested anywhere, so I grant. For the examiner it was a quick grant, so why bother.

Dear Look at things,

Thank you for the reply. I’m sorry if I gave the impression I’m trying to defend the EPO. I was just sceptical of the criticism directed at the examiner (who granted in 2007, before the drive for more efficiency) without much concrete evidence.

I know that an opposition can sometimes unexpectedly fail (either through lack of support from the client or a representative’s mistake), but if the examiner really made such a blatant mistake by granting, an opposition should normally succeed. This made me question whether the prior art was really that easily available to deny a grant (the wikipedia entry for Teff in 2002 consists of merely six short sentences).

You provide a convincing potential inventive step attack, thank you for that, and I agree it probably should not have been granted (although broad claims can be perfectly fine IMO).

Dear Anonymous,

That’s for your reply. I fully agree that broad claims are fully justified if the contribution to the art is in accordance.

This is not what seems to be the case here. There is a long line of case law saying that when the skilled person is assessing inventive step, it should not limit himself to the specific technical area of the patent, but look also at neighboring areas, or even at general areas, if he he’s reasons to believe that he can find there a solution to his problem.

If it is known in general that storing grain before milling improves the quality of baked products, and this is the case, then the search should extend to such an area. It might well be that by applying stupidly the problem solution approach a quick grant can be justified, but certainly not when using common general knowledge, or even common sense.

Searching the right prior Art is not an easy task, but it is not impossible, provided it is based on a genuine effort. Here the effort was manifestly lacking.

When you look at the Dutch decision it has cost around 200.000€ to start with, to the proprietor for his missed attempt proprietor to enforce a not valid patent.

But this is an aspect, the average examiner does not care about, and he cannot be blamed for it in times when a high production target is required from him.

I agree with you that no claim granted by the EPO was ever “clear” to a level of 100%. My understanding is that the EPO is hot on clarity at the moment is because it is a metric that is being used to measure patent quality. I do not believe there was ever a significant issue with clarity post-grant prior to this crusade. My worry is that the EPO as an organization is aiming for claims having 100% clarity and perfect ‘form’.

Thorsten,

You wrote:

.

This is not quite correct. The patents at stake before the court at The Hague were the two Dutch national patents NL1023977C2 and NL1023978C2.

Claim 1 of NL1023977C2 as granted reads as follows:

[NL] 1. Meel van een graan, waarbij het graan tot het genus Eragrostis behoort, met het kenmerk dat het valgetal van het graan op het moment van vermalen ten minste 1.01-maal hoger is dan op het moment van oogsten van het graan, bij voorkeur ten minste 1.05-, bij grotere voorkeur ten minste 1.20-maal hoger, bij nog grotere voorkeur ten minste 1.30-maal hoger.

[EN] 1. A flour of a grain, whereby the grain belongs to the genus Eragrostis, characterized in that the falling number of the grain at the moment of grinding is at least 1.01 times higher than at the moment of harvesting the grain, preferably at least 1.05, more preferably at least 1.20 and still more preferably at least 1.30 times higher.

According to point 2.10 of the decision, the proprietor submitted on 9.5.2014 the following new main request for NL’977:

[NL]: 1. Meel van een graan, waarbij het graan tot het genus Eragrostis behoort, met het kenmerk dat het valgetal van het graan op het moment van vermalen tussen 280 en 420 ligt, bij voorkeur tussen 300 en 400 en bij grotere voorkeur tussen 320 en 380 ligt.

[EN]: 1. A flour of a grain belonging to the genus Eragrostis, characterized in that the falling number of the grain at the moment of grinding lies between 280 and 420, preferably between 300 and 400, more preferably between 320 and 380.

As the court acknowledges in its transcript, the proprietor replaced features of claim 1 as granted with different ones. This would be immediately unacceptable under Art. 123(3) and 138(1)(c) EPC. A member state has however no obligation to actually implement any part of Art. 138. Furthermore, NL’977 is a national patent, and not an European one. In any case, this bait-and-switch of subject-matter is duly noticed in the decision, but wasn’t objected to at all.

Yet, upon verification, there appears to be a corresponding provision in Art. 75(1)(d) of the Netherlands Patent Act (“ROW 1995”):

NL: Een octrooi wordt door de rechter vernietigd voor zover: […] na octrooiverlening uitbreiding van de beschermingsomvang is opgetreden; […] [emphasis added]

EN: A patent shall be annulled by the court to the extent that an extension of the scope of protection occured after grant.

This language mirrors IMO Art. 138(1)(d) EPC: “… a European patent may be revoked with effect for a Contracting State only on the grounds that: […] the protection conferred by the European patent has been extended”.

Point 5.7 of the technical opinion of Netherlands patent office dated 21.10.2015 (see documents in national register) in the opposition procedure underlying the present case mentions Art. 75(1)(d) of the law, but as far as I can make any sense of that section, the reasoning seems to allude to the notion of added-subject matter rather than an extension or shifting of the scope of protection, and finds there is none. I find this rather odd, especially since there is no reference to the patent as filed or granted. Instead there is a discussion of documents B14, B18 and B20.

None of the numerical ranges recited in NL’977 are congruent with any of those claimed in EP’287 (closed ranges vs, open-ended ranges; different end-points), even though EP’287 claims the priority of NL’977. This casts serious doubts about the validity of the latter application’s priority claim — unless you want to go down the partial priority rabbit hole… Were the numerical ranges chosen because they truly reflected a surprising technical effect, or are they wagers on plausible values that would capture the entire field?

Despite the differences, the proprietor didn’t hesitate to mention the cookie-cutter positive international opinion on EP’287, a parent of NL’977 (point 4.19 of the court decision), as an argument in favour of patentability (Michel Audiard lässt grüßen…).

So in a sense, despite the differences, the court’s decision is still relevant for EP’287. The case was on the basis of a lack of inventive step over document B9, an obscure newsletter circulating around Dutch farmers trying to introduce the crop. This document was obviously unavailable to the EPO at the time of the PCT search (and even the national search of NL’977, which was done by the same examiner at the EPO on the account of the Netherlands patent office). B9 doesn’t mention any specific ranges.

How could these two patents been prevented without this rare document?

I might still have something to say after this long preamble, but the commenting window is woefully short on this blog.

To be continued… [Hopefully I will be able to complete this while it is still possible.]

Thank you, Roufousse, very informative. Should you encounter problems in entering part II of your reply, please notify me. I would then post it separately.